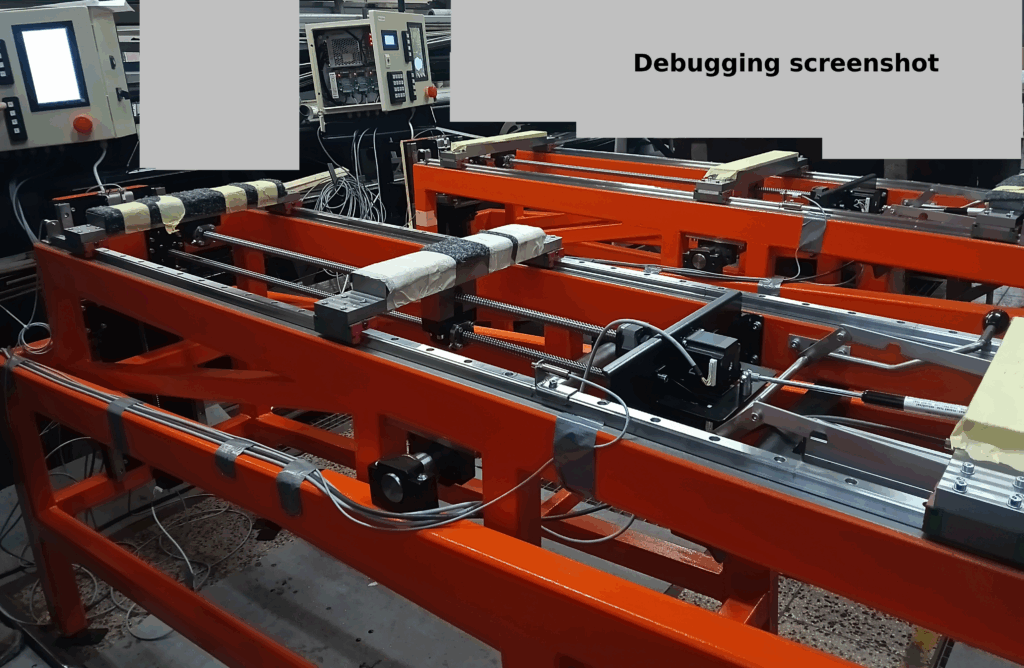

The track gauge calibration stand represents a modern solution based on existing equipment, but with the possibility of installation in a measuring vehicle. The system is equipped with three stepper motors and precision screws for automatic adjustment of all measurement parameters. The measurement repeatability is 0.8 µm. After calibration, the measurement accuracy is the same. The tilt measurement range is ±230 mm and the range of measured gauges is from 740 to 1500 mm. The device is certified by the Czech Institute of Standards.

Technical Specifications

Control Motors:

- Motor 1: Cant adjustment (PK) with maximum torque 0.04 Nm

- Motor 2: Gauge adjustment (RK) with rotation speed approx. 75 rpm

- Motor 3: Groove width (r) and distance (A) adjustment

All motors are equipped with overload protection and microswitches for determining end positions.

Control and Display:

- Graphical color 7″ display for showing current values

- Intuitive control with numeric and function buttons

- USB connector for external computer connection

- Automatic initialization and system calibration

Supported Track Gauge Types

The system supports more than 20 types of track gauges including standard, narrow, and special track gauges for various applications.

| Track Gauge Type | Gauge (mm) | Cant min/max | Groove Width (mm) |

|---|---|---|---|

| RCA1435 | 1435 | -30/+200 | 50-83 |

| RCS 1435 | 1435 | -30/+200 | 100-130 |

| RCA switch 1000 | 1000 | -30/+150 | 50-83 |

| 760mm without control | 760 | -220/+220 | 40-83 |

Operating Modes

Manual Mode:

Control using keyboard and buttons directly on the device. All values are displayed on the graphical display in real time. The system automatically sets parameters according to the selected track gauge type and performs validity checks of the set values.

Remote Control:

Communication via USB interface with support for INI (initialization), VOL (type selection), SET (value setting) and GET (value reading) commands. Enables automation of the entire measurement process and export of measured data to an external computer.

Calibration and Maintenance

The system enables advanced calibration of all three motors using an external computer. Calibration curves can contain up to 80 points and are stored in the device’s flash memory. The system checks curve monotonicity and enables export/import of calibration data.

Maintenance:

- Adjustable overload protection for motors

- Diagnostics of all functions via USB interface

- Simple component replacement during maintenance

- Firmware update capability

Key Advantages

Measurement Accuracy: High accuracy thanks to stepper motors and precise measuring screws enables achieving required precision of track gauge calibration.

Automation: Automatic parameter setting according to track gauge type and possibility of measurement repetition with minimal operator intervention.

Universality: Support for a wide range of track gauge types and gauges for various applications in railway transport.